Roadmap

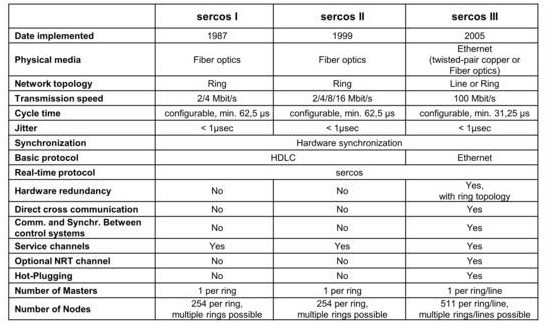

Since the start of the 1990s, the Sercos digital drive interface has developed into a globally accepted real-time communication standard for demanding motion control applications. Its attractiveness is based on the interface’s excellent technical features – in particular in terms of real-time, performance and reliability – and the extremely large product and supplier spectrum. The recipe for success of the third generation of Sercos, which was launched onto the market with initial prototypes in 2005, is: “Use of the transmission medium and the protocol of Ethernet under preservation of the tried-and-tested Sercos mechanisms.” Today, Sercos III is an established global industry standard and still uses the same hard real-time mechanisms now in several million nodes. Only three technology generations in two decades have marked and are marking the respective current state-of-the-art for demanding real-time communication.

|

Manufacturer and user requirements continuously impact specification updates. In the process, the expansions and improvements are based both on the communication protocol and the various function and device profiles. Each expansion of the specifications is fully compatible with the existing specifications. Thus, a high degree of standardization and interoperability of devices from various manufacturers continue to be ensured.

The approved specifications are made available as electronic documents in PDF format and additionally via a Sercos Wiki (https://wiki.sercos-service.org/current/Main_Page). The Sercos Wiki is a fantastic document to accompany development and a comprehensive reference book due to the way in which parts of documents and individual documents are linked.

Members of the Sercos user groups have access to non-public protocols and specification drafts, which they can benefit from as an informational and competitive advantage on the market. Moreover, members have the opportunity to influence technical development and the strategic direction.

Currently, the Sercos International bodies are working on new function profiles to expand the existing specifications. The demands posed by increasing application diversity are also met. The innovations include function profiles for measuring and testing, servo drive power and control units, and controller-to-controller communication. A profile for preventive maintenance and servicing for plants and machinery is also to be specified. This condition monitoring profile will be based on the VDMA standard "Fieldbus-neutral reference architecture for condition monitoring systems in factory automation." Additional results from the machine initiative in partnership with ODVA and the OCP Foundation will also be taken into account.